Sternum Sutures

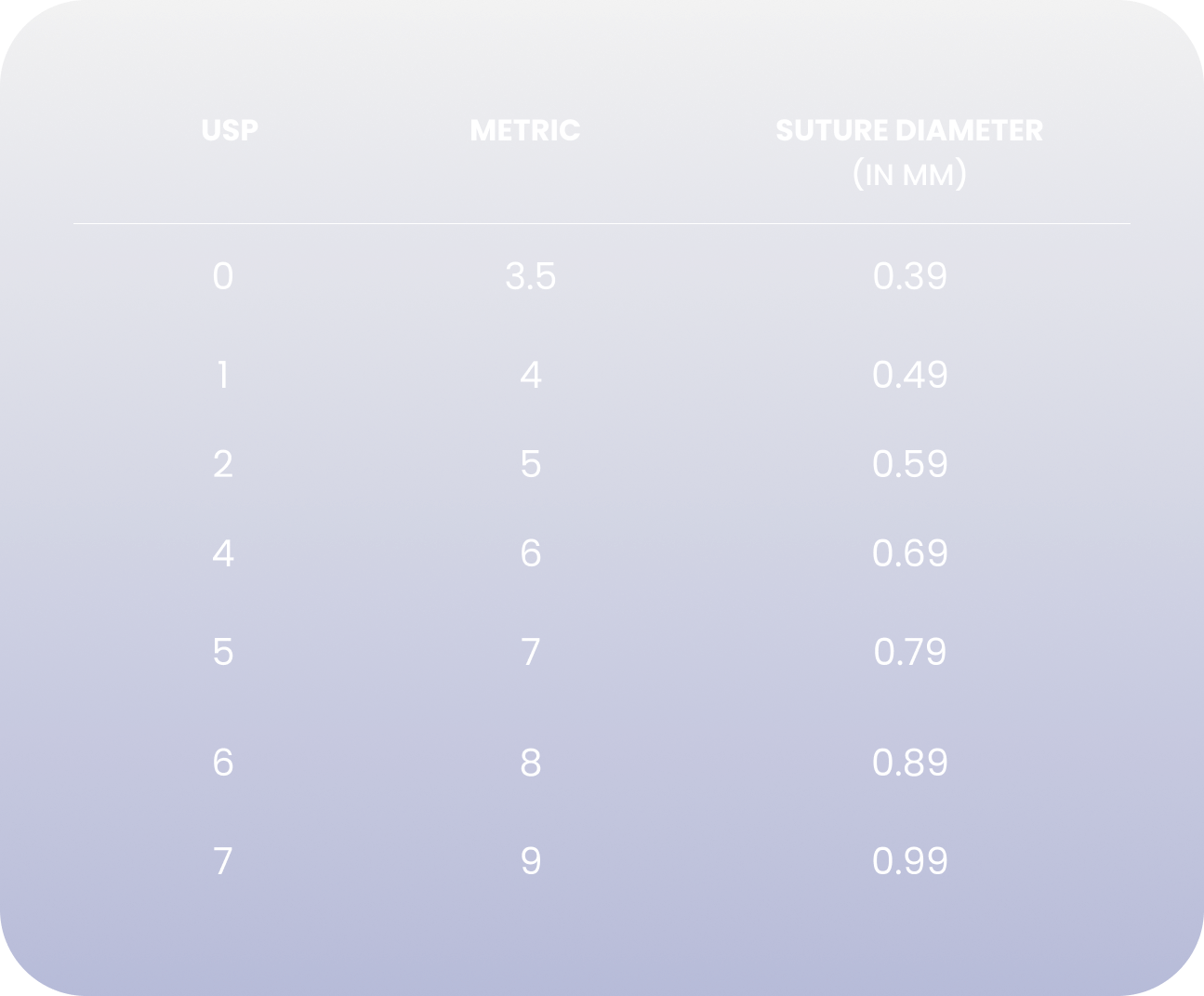

Sternum sutures represent a new development in sutures for sternum closure after median sternotomy. For suture sizes USP 5,6 & 7 the sternal suture is welded to the needle rather than using the conventional crimped design offered by other manufacturers. (Smaller suture sizes USP 0,1,2 & 4 are offered in channel or drilled-end attachment)

As a result of this development, for these 3 sizes Quality Needles now offers a product which combines an aesthetically pleasing needle-suture joint with attaching strength approaching the ultimate strength of the suture!

The fact that our Company is certified under ISO 9001-2008/ISO13485:2003 & all the products are CE Marked by DNV is a further assurance of consistent product quality. For our products we use high grade stainless steel of the finest quality.

These high quality materials are the basis for a product that combines maximum stiffness and strength coupled with ductility.

Sternum Wire

- Is manufactured from implantable high grade stainless steel of the highest quality (as per AISI 316 LVM (low carbon vacuum melt).

- Its inherently consistent tensile strength in combination with its good twisting & knotting properties guarantees a high degree of safety.

- More pliable wire conforms closely to the contours of the sternum facilitating good closure

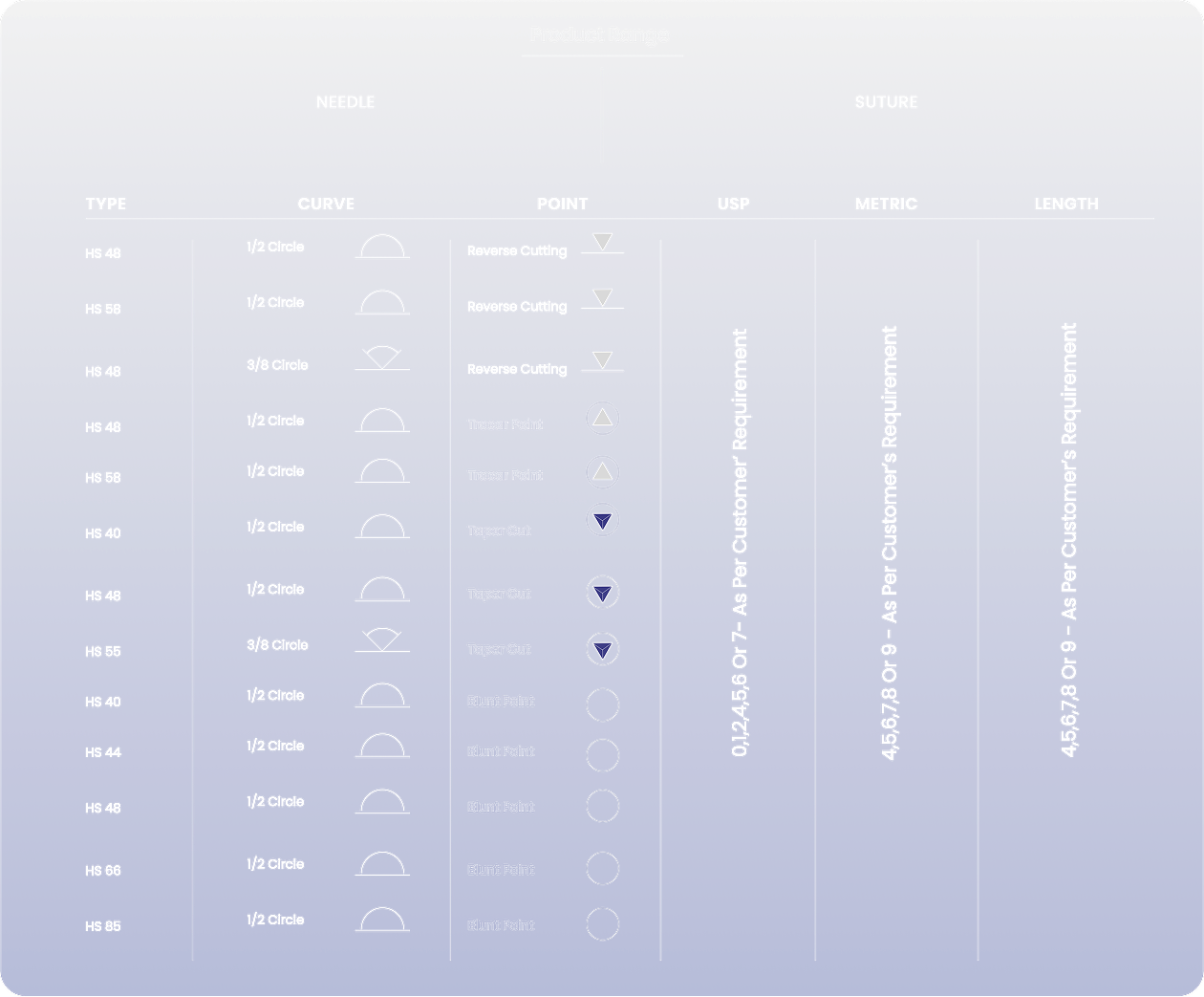

Sternotomy Needles

- Are manufactured exclusively from selected high grade, martensitic stainless steel to DIN Werkstoffnummer 1.4031 (roughly equivalent to AISI 420), duly hardened and tempered.

- Couple high stiffness with high strength and resistance to breakage.

- Guarantee low penetration force and minimum trauma through precise geometry. control of point

are available with several needle types e.g.

a) Round bodied needles, with Conventional cutting (Trocar point.)

b) Triangular Conventional Cutting point. needles with or reverse

c) Taper cutting point

d) Round bodied needles, with blunt point

Maximum sharpness of the needles is achieved by individual grinding of the needle points on special purpose machines. We also offer a special ‘cross ground’ point geometry with hollow grinding for premium performance. Further, the profile of the needle tip has convex to the point, these contributing to a stronger point which is less prone to damage.

Sternotomy Needle Suture Connection

- For USP sizes 5,6 & 7 are manufactured using a specially developed welding process under precise microprocessor control, as a result of which highest standards of safety and quality are guaranteed. This attachment is aesthetically pleasing and exceptionally strong.

- Failure of the needle-suture joint is almost completely eliminated since joint strength is comparable with the ultimate tensile strength of the suture wire.

- Is fully free from sharp edges, minimising tissue trauma.

Packaging

Products will be supplied as nonsterile and bulk packed in packets of 100. Special packing can also be done as per customer’s specific requirements.

- Either needles with sutures attached or only needles (without sutures) can be supplied as desired.

- Option of channel or drilled-end types for attachment of sutures to needles available as per customer’s request.

- Any other shape/size/type of sternotomy needles, including pediatric sizes, can supply as required by customer. Different curvatures, needle lengths and shank profiles can be developed to suit any particular requirements.